FCX24 Lemur – Reverse Engineering and Improvement

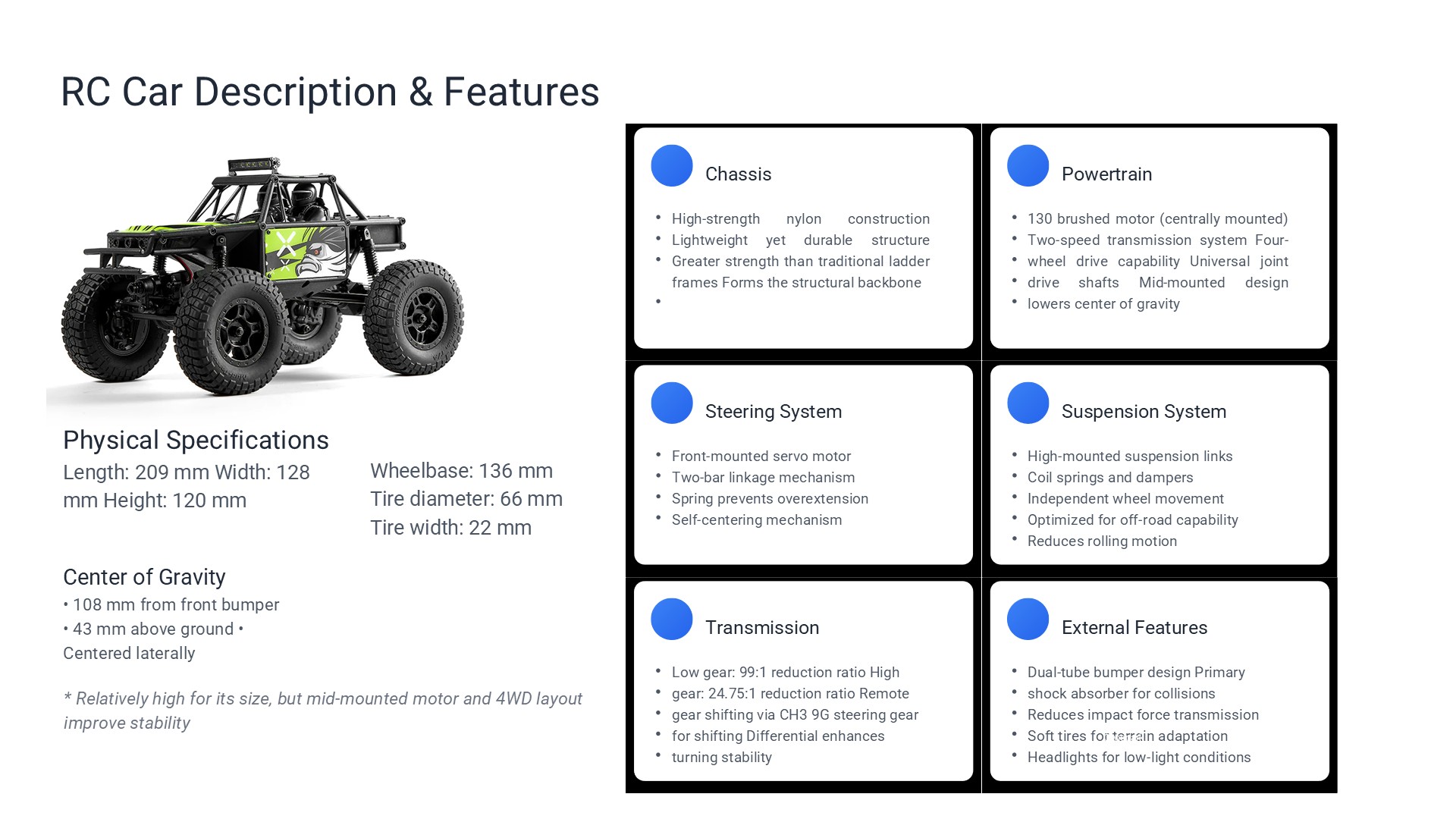

This project involved complete disassembly, 3D modeling, and mechanical analysis of the FMS FCX24 Lemur 1:24 RC Car.

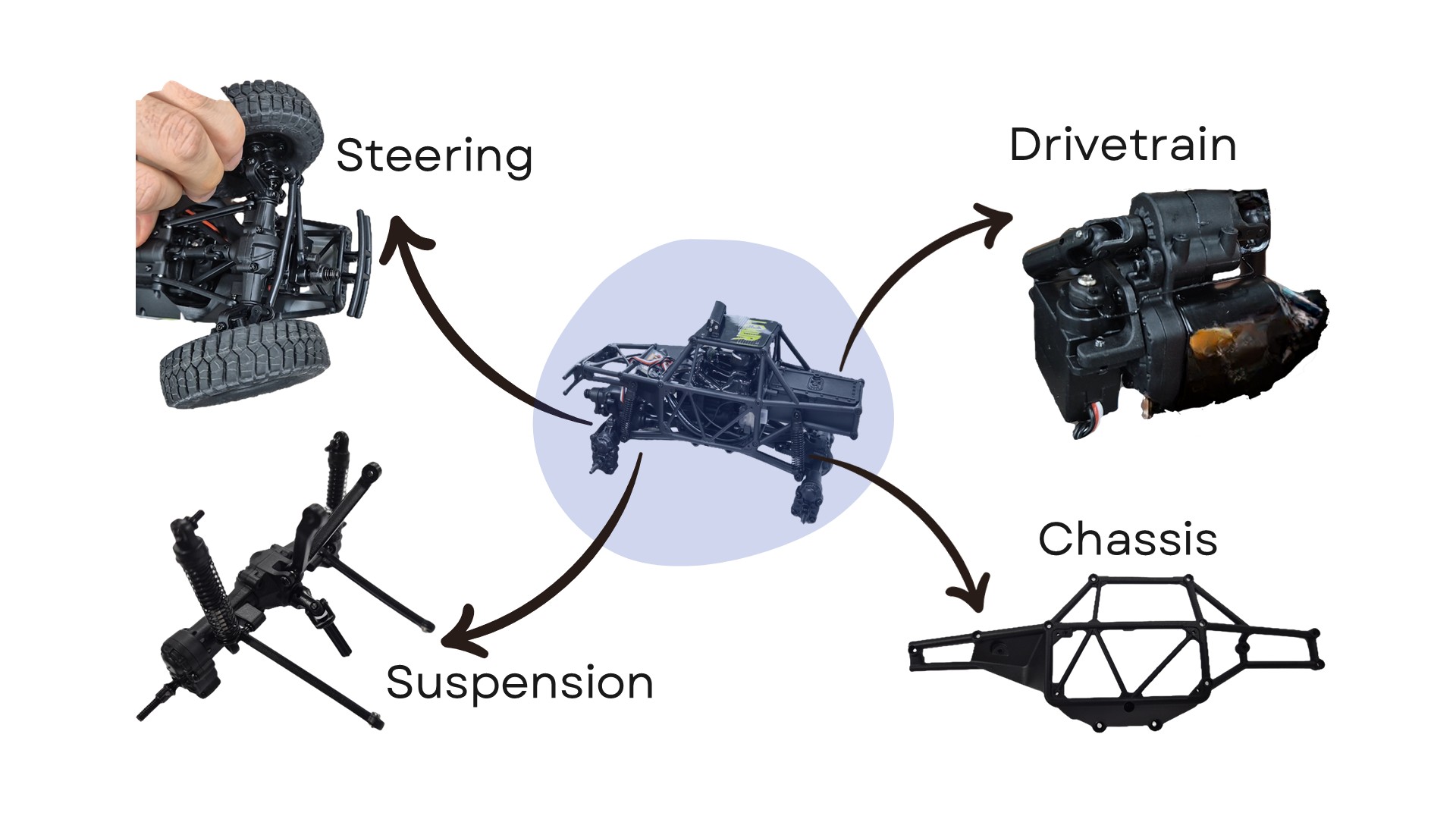

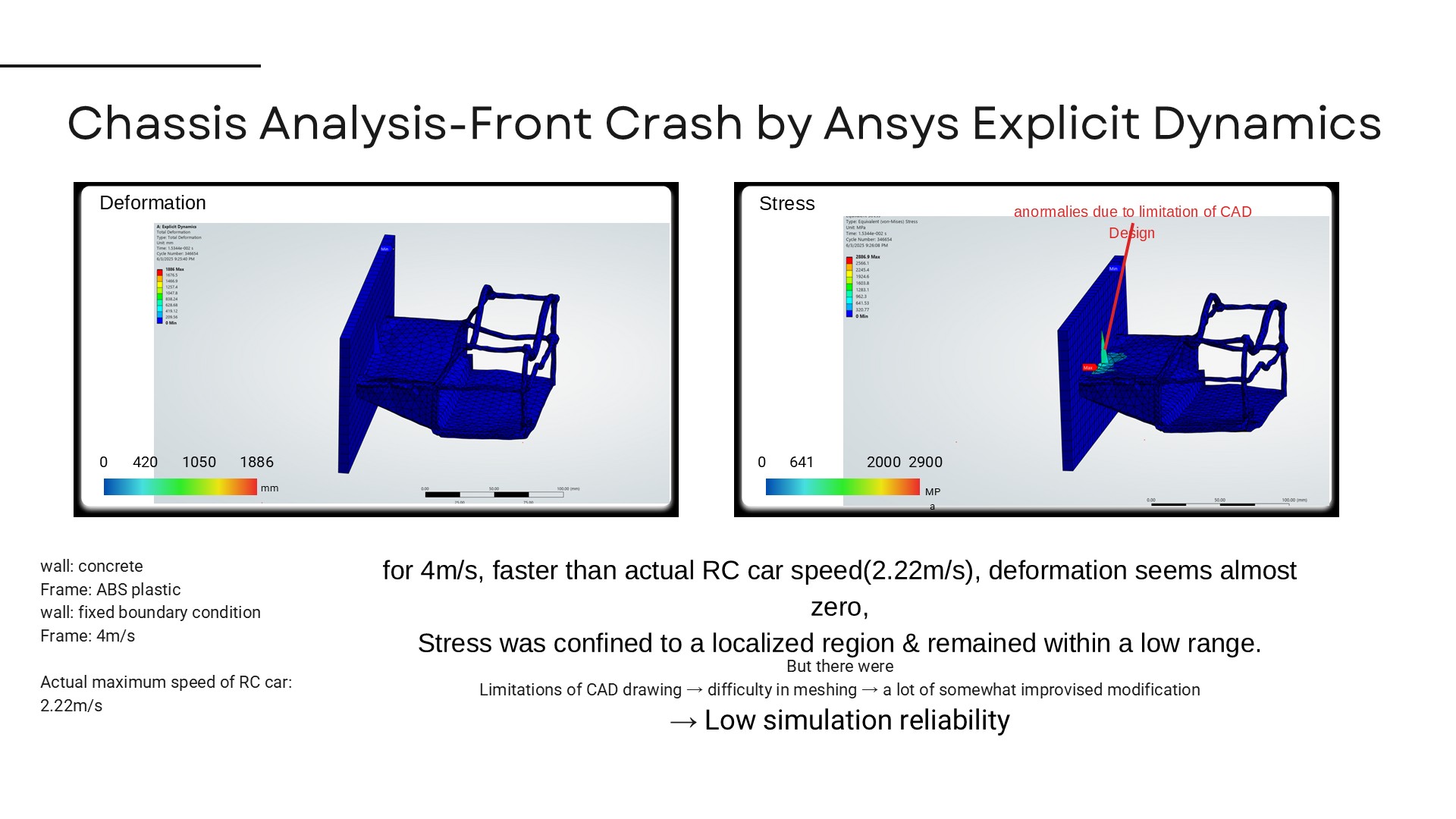

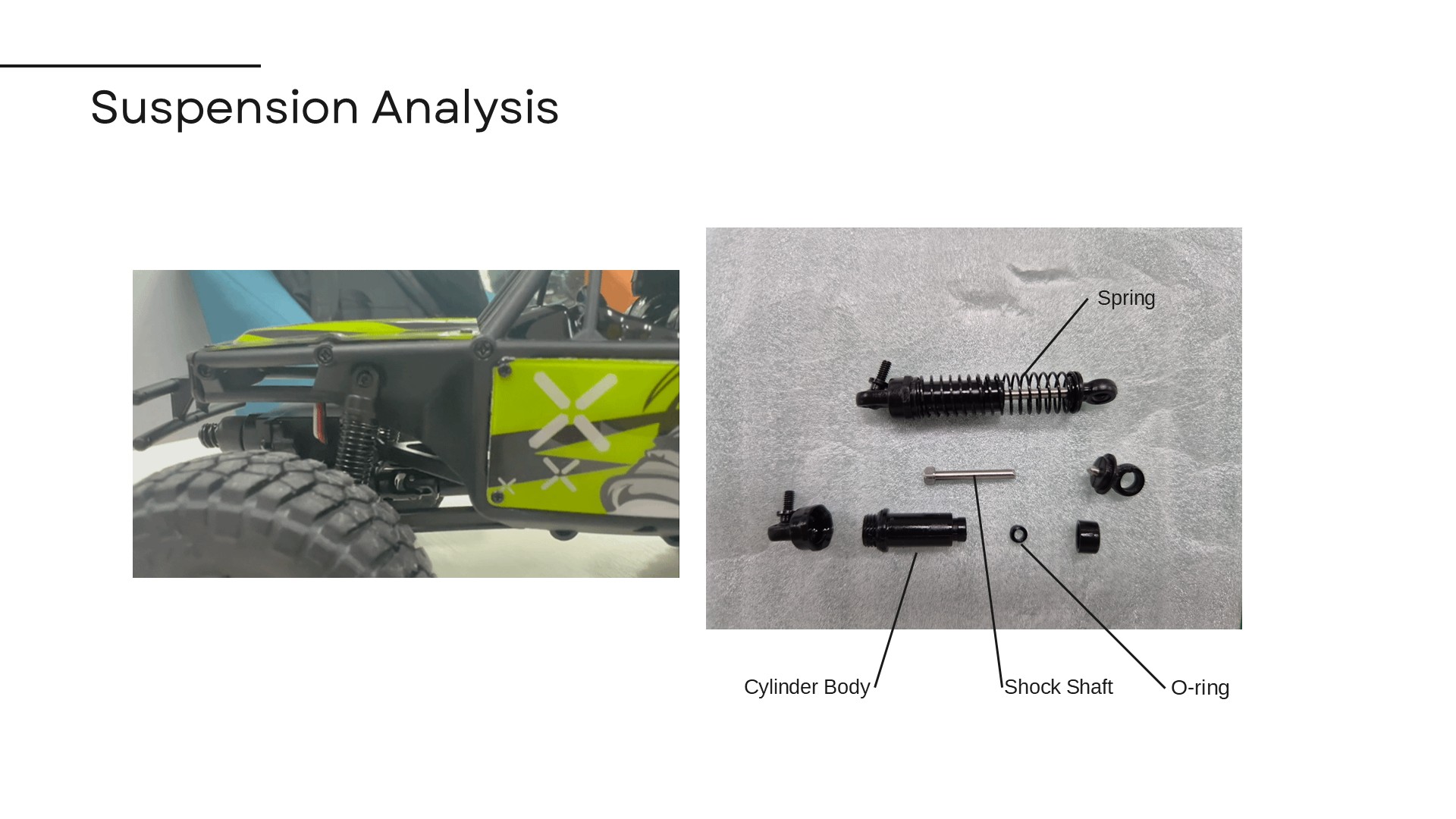

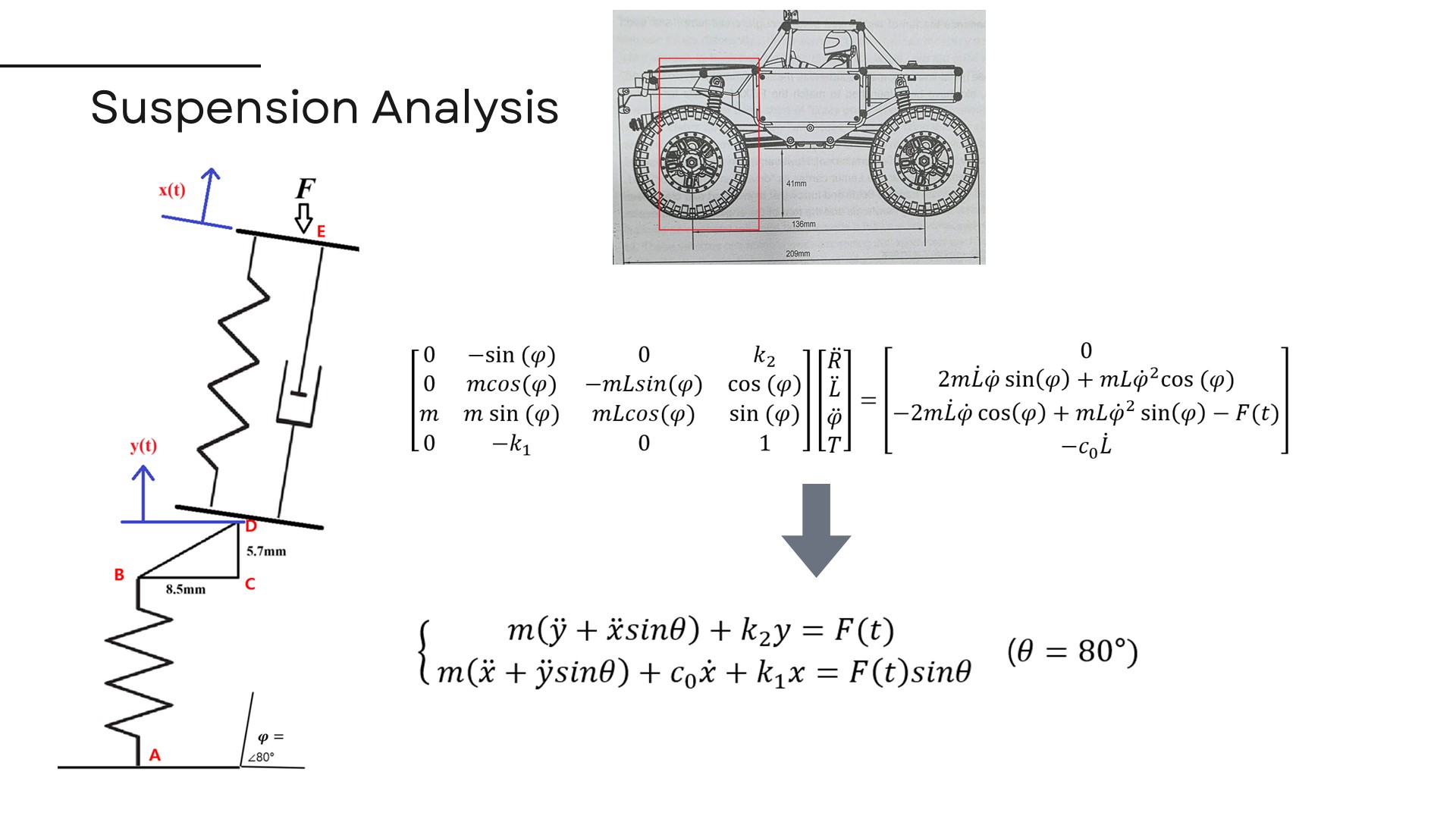

The work included detailed studies of its chassis, drivetrain, suspension, and steering systems using Fusion 360 and ANSYS to explore real automotive dynamics on a miniature scale.

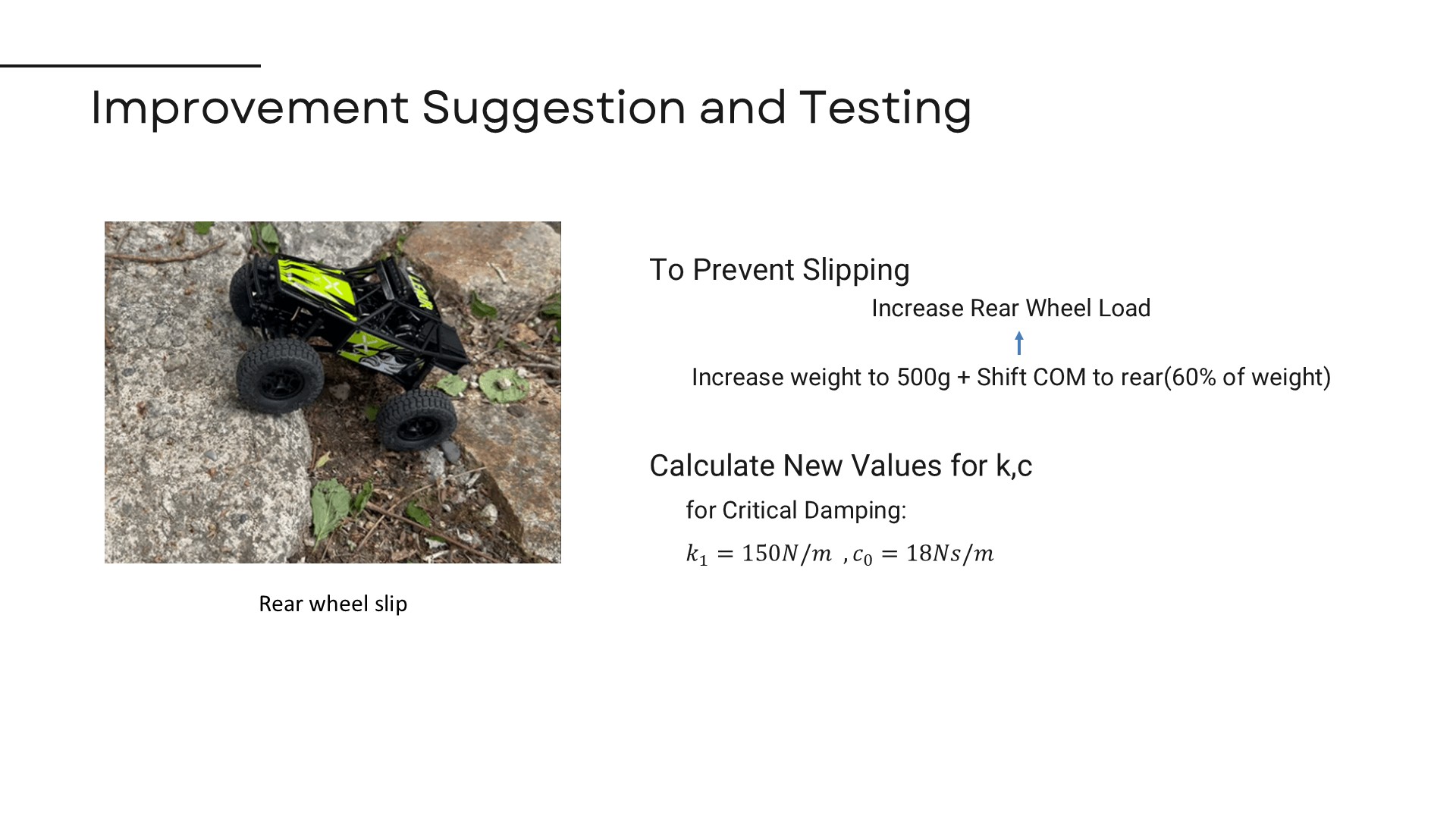

Finally, to prevent rear-wheel slip our team designed and tested a custom-damped suspension.

Key takeaways:

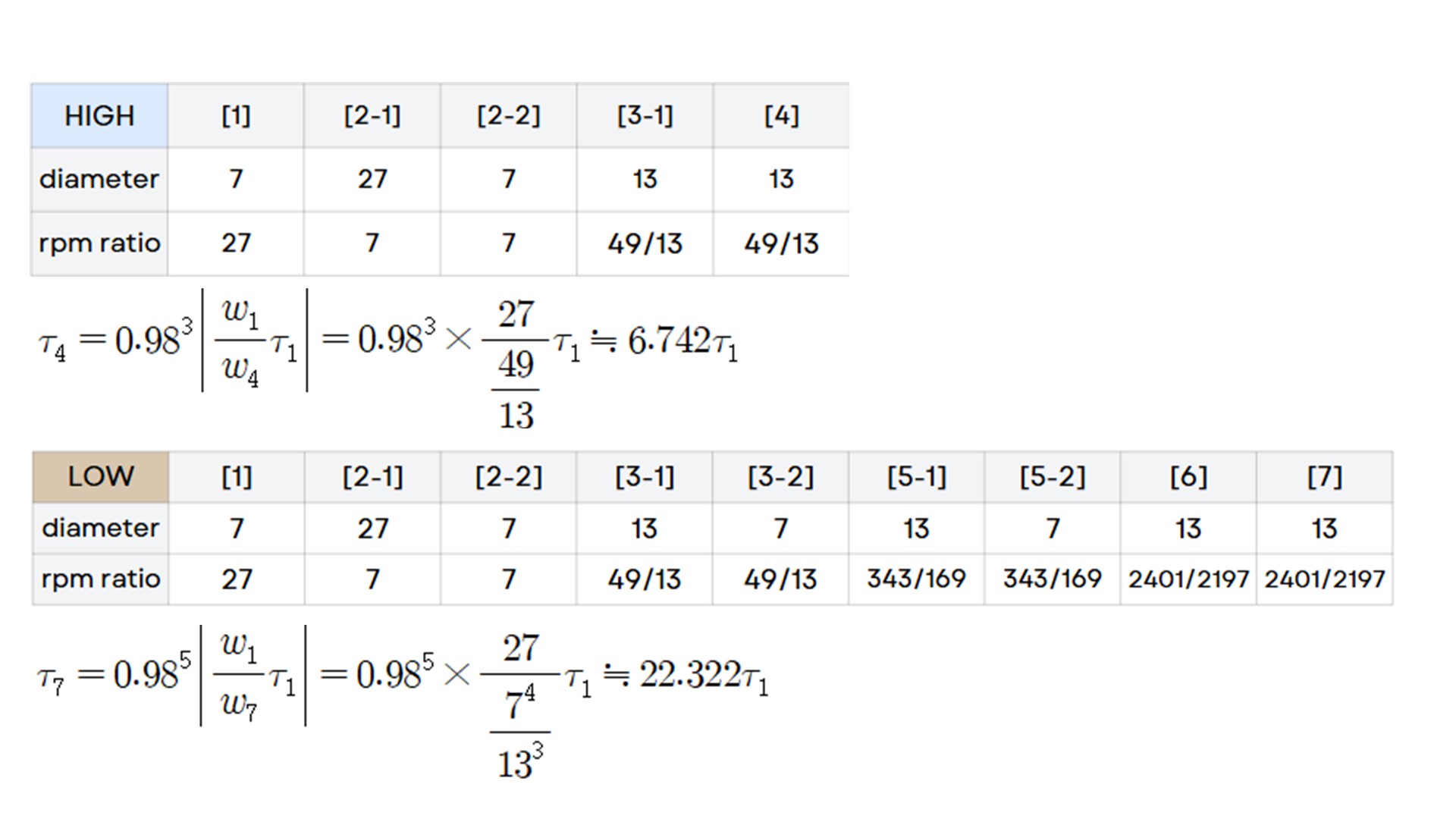

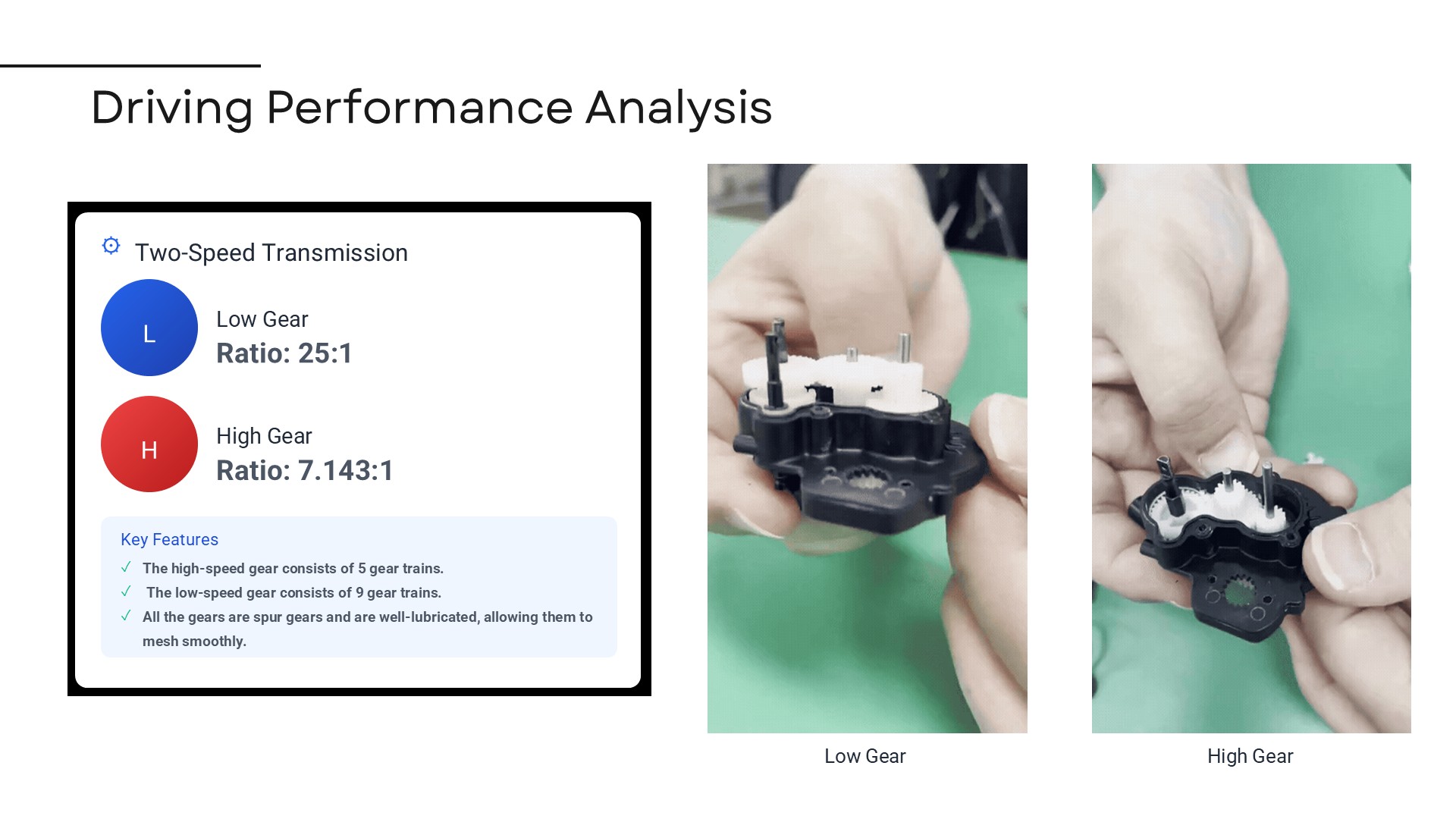

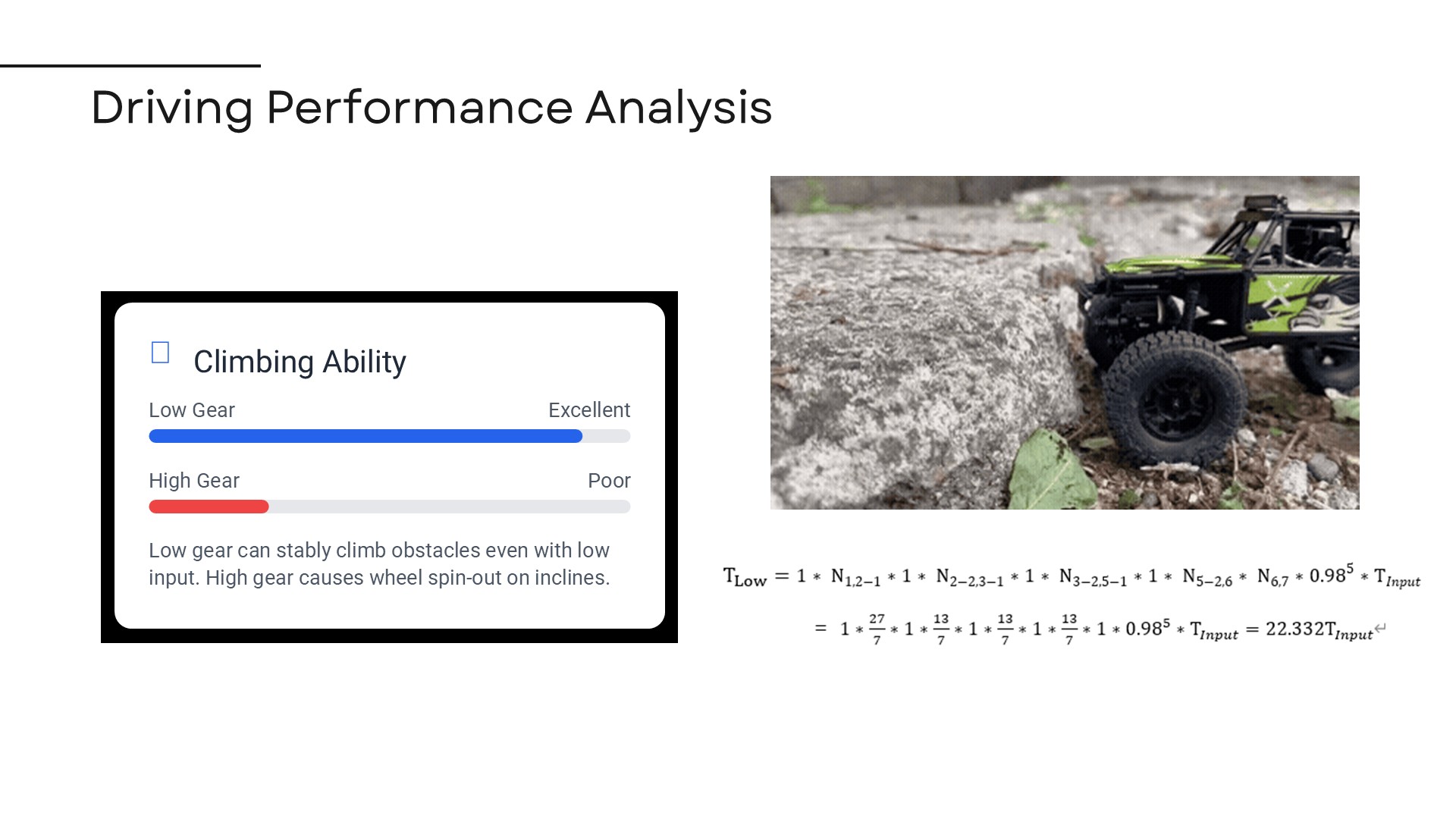

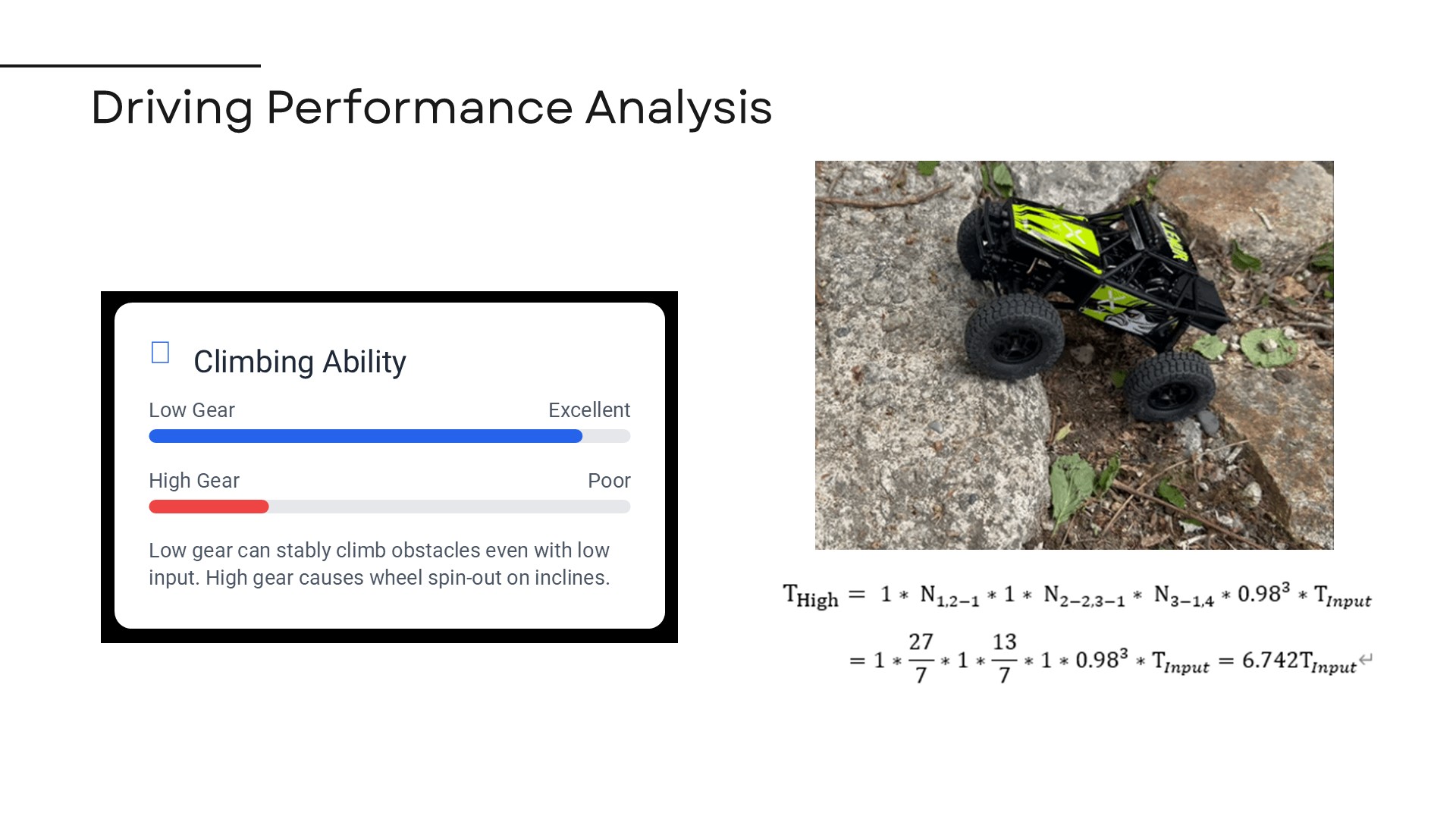

- Achieved 3.3× torque difference between gears via two-speed transmission analysis.

- Verified chassis strength (>250 N vertical load capacity) and impact safety through simulation.

- Designed and validated a new damper (18 Ns/m) reducing slip and improving traction under incline conditions.

Introduction

Analyzed the FCX24 Lemur RC car to understand real-vehicle dynamics using an accessible small-scale platform.

Analysis

Conducted structural and dynamic analysis on chassis, suspension, steering, and drivetrain using CAD and simulation.

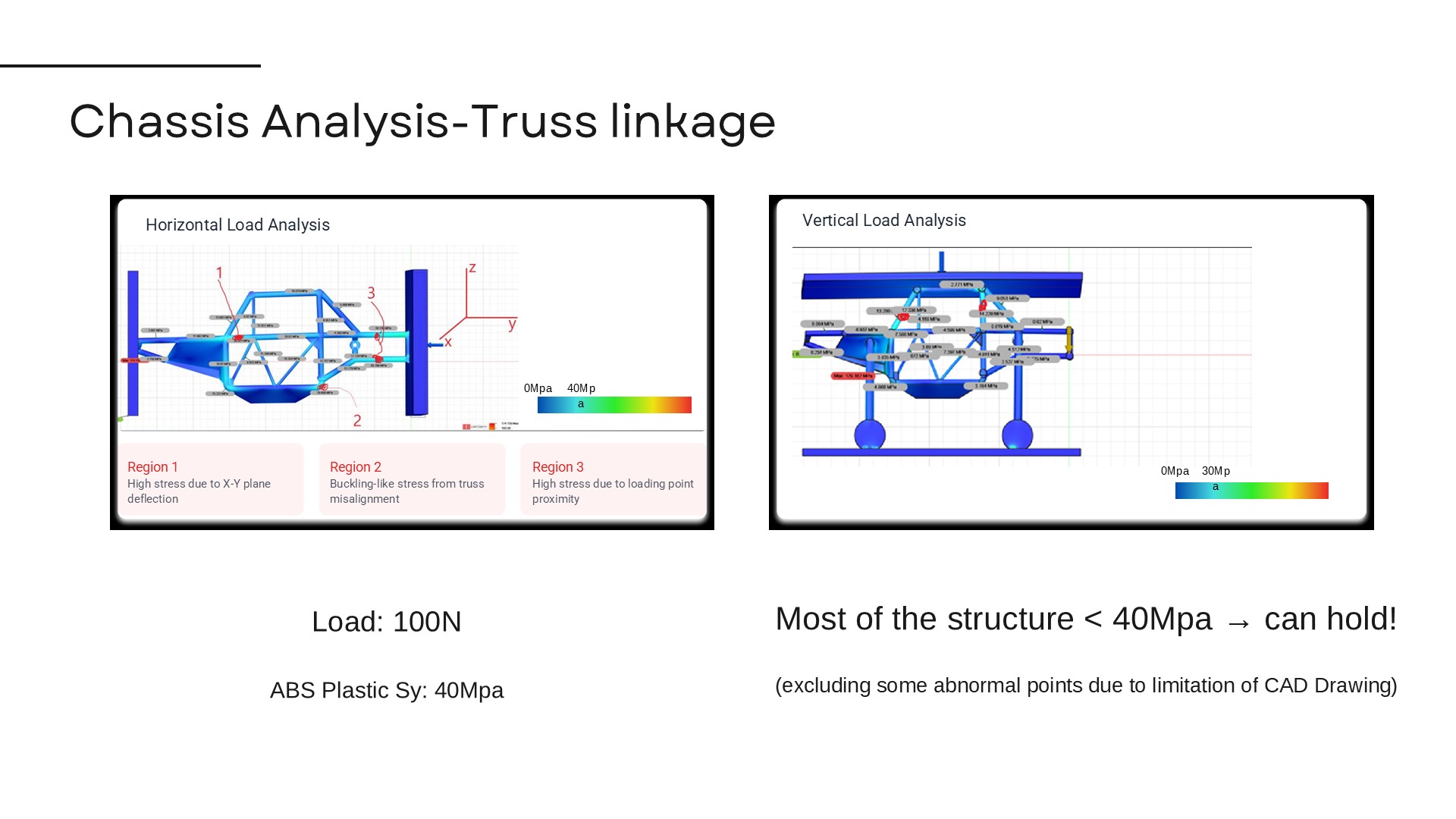

Chassis

Simulated horizontal and vertical loads in Fusion 360 and ANSYS; chassis withstood > 250 N vertically with minimal deformation.

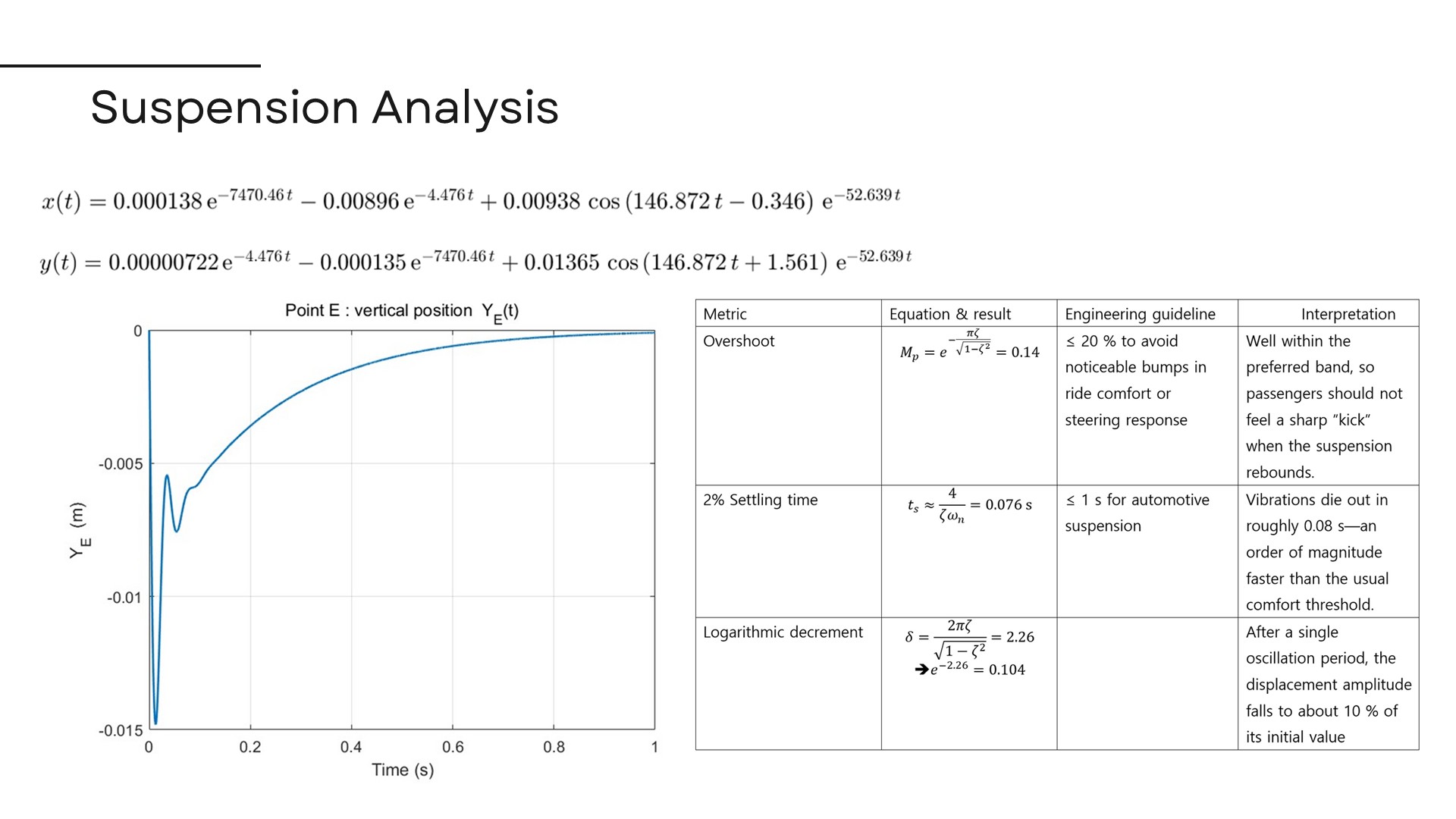

Suspension

Modeled spring–damper behavior and measured stiffness/damping values (k₁ = 2141 N/m, c₀ = 20 Ns/m) for optimal ride stability.

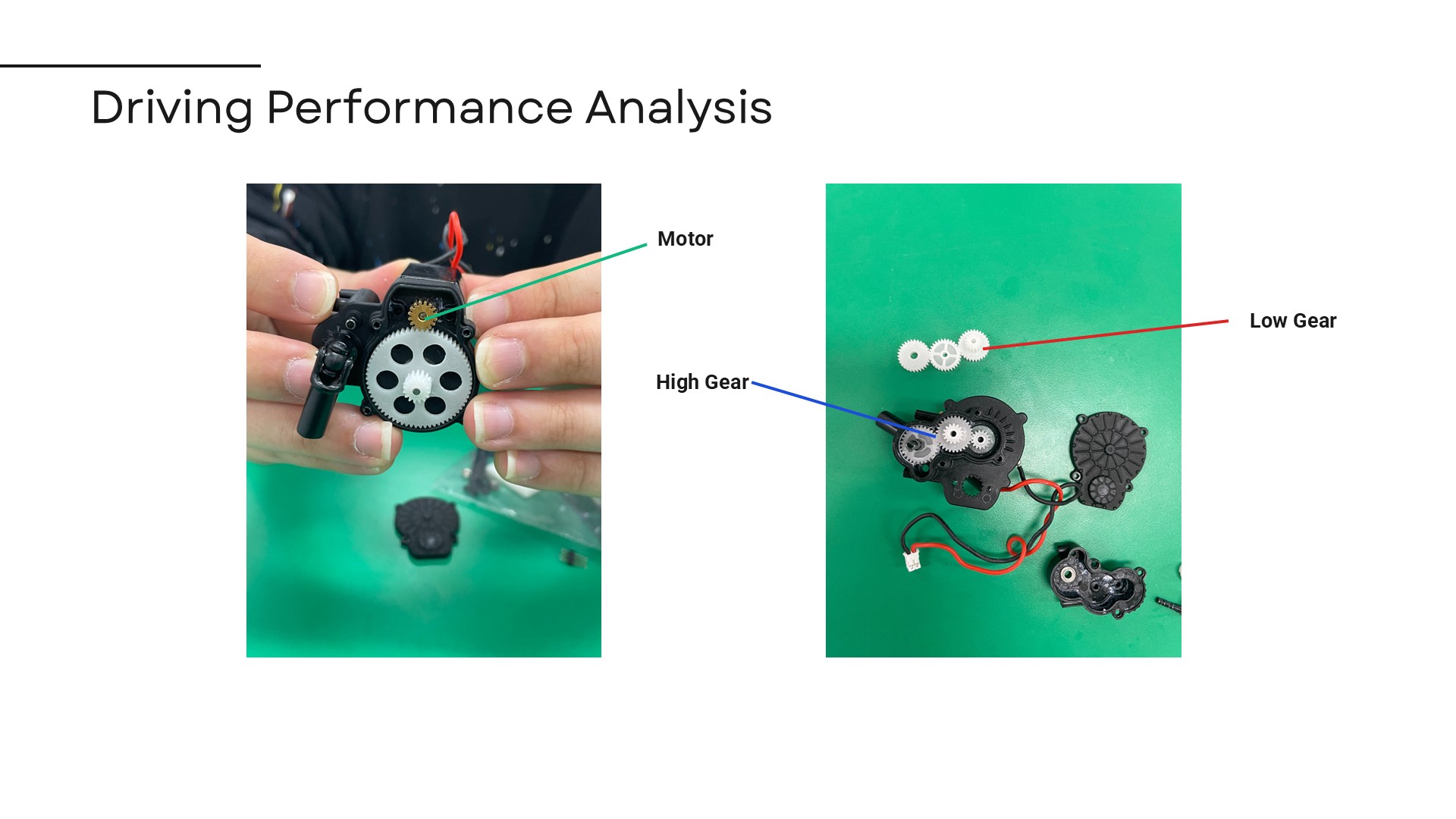

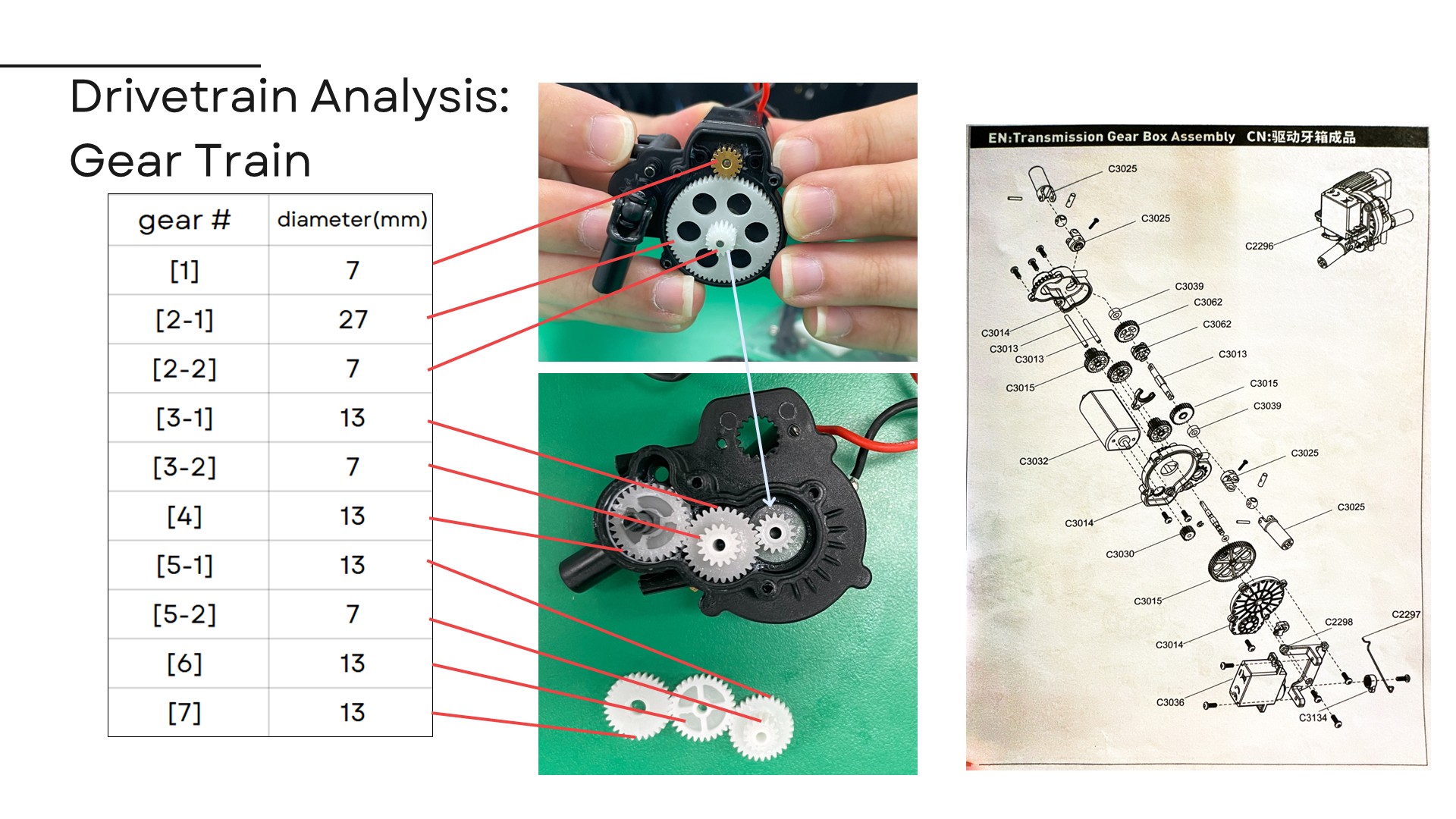

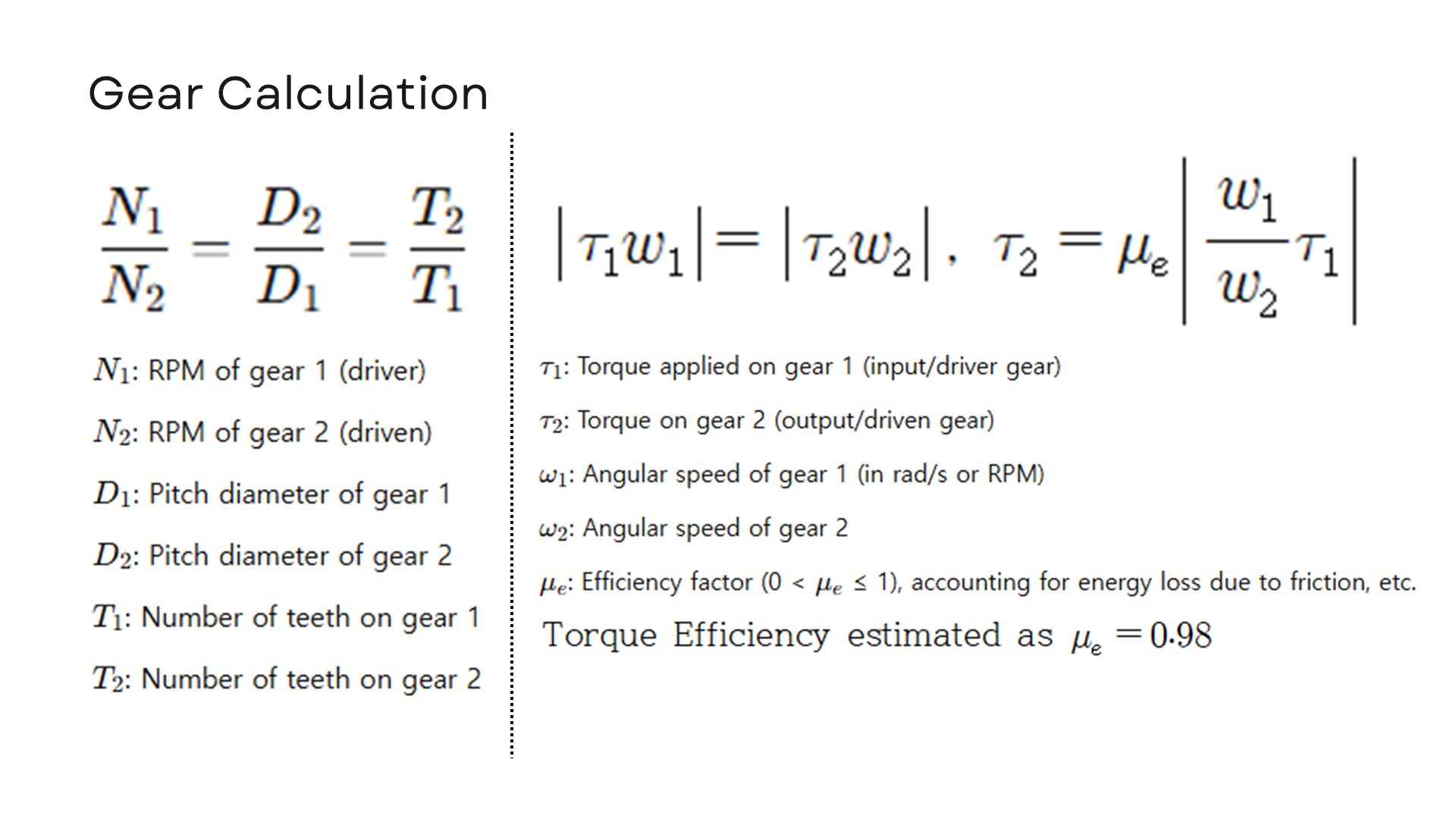

Steering & Drivetrain

Calculated gear ratios and torque multipliers (22.3× low-gear vs 6.7× high-gear); confirmed inverse relation between speed and torque.

Improvement

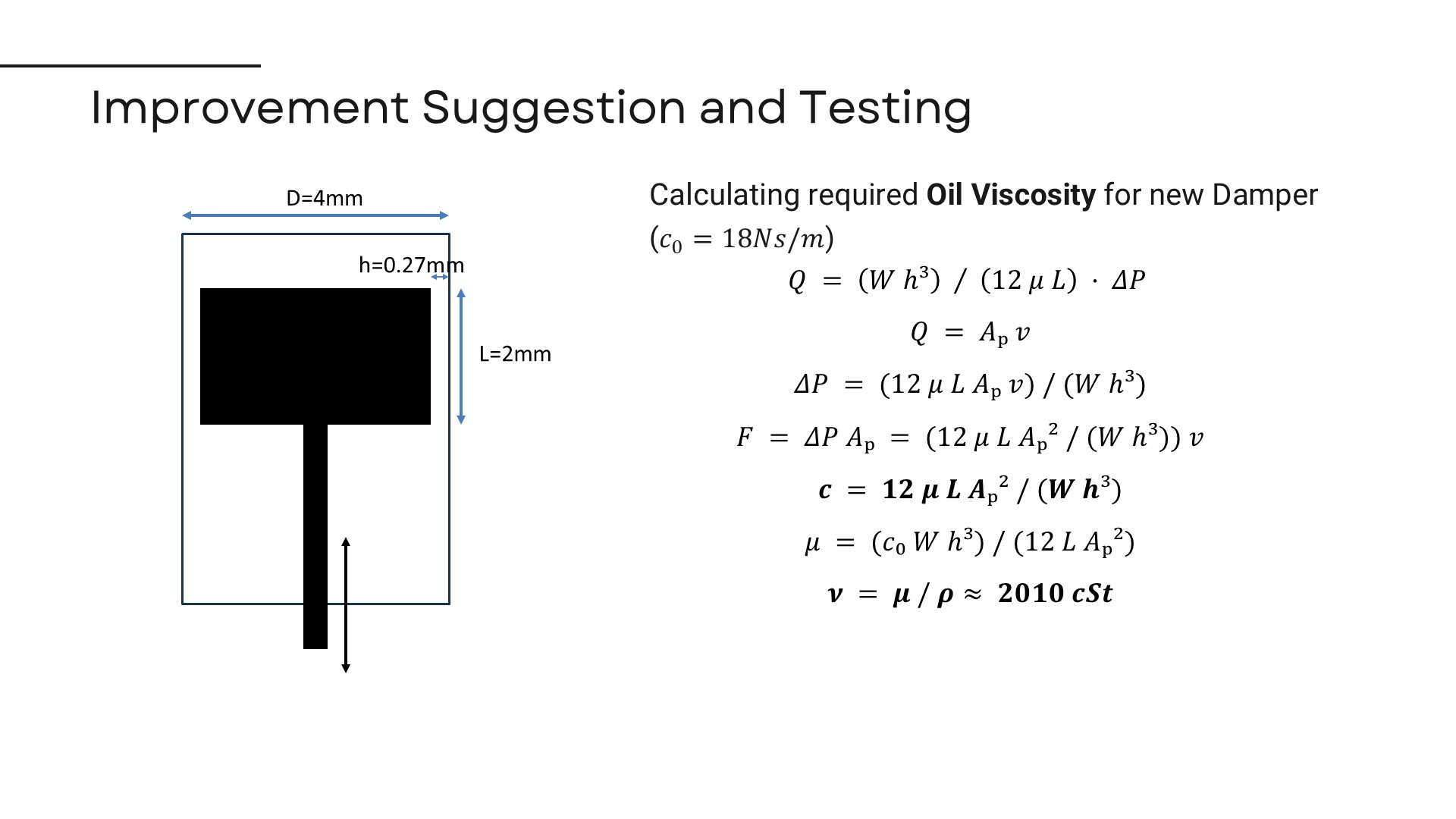

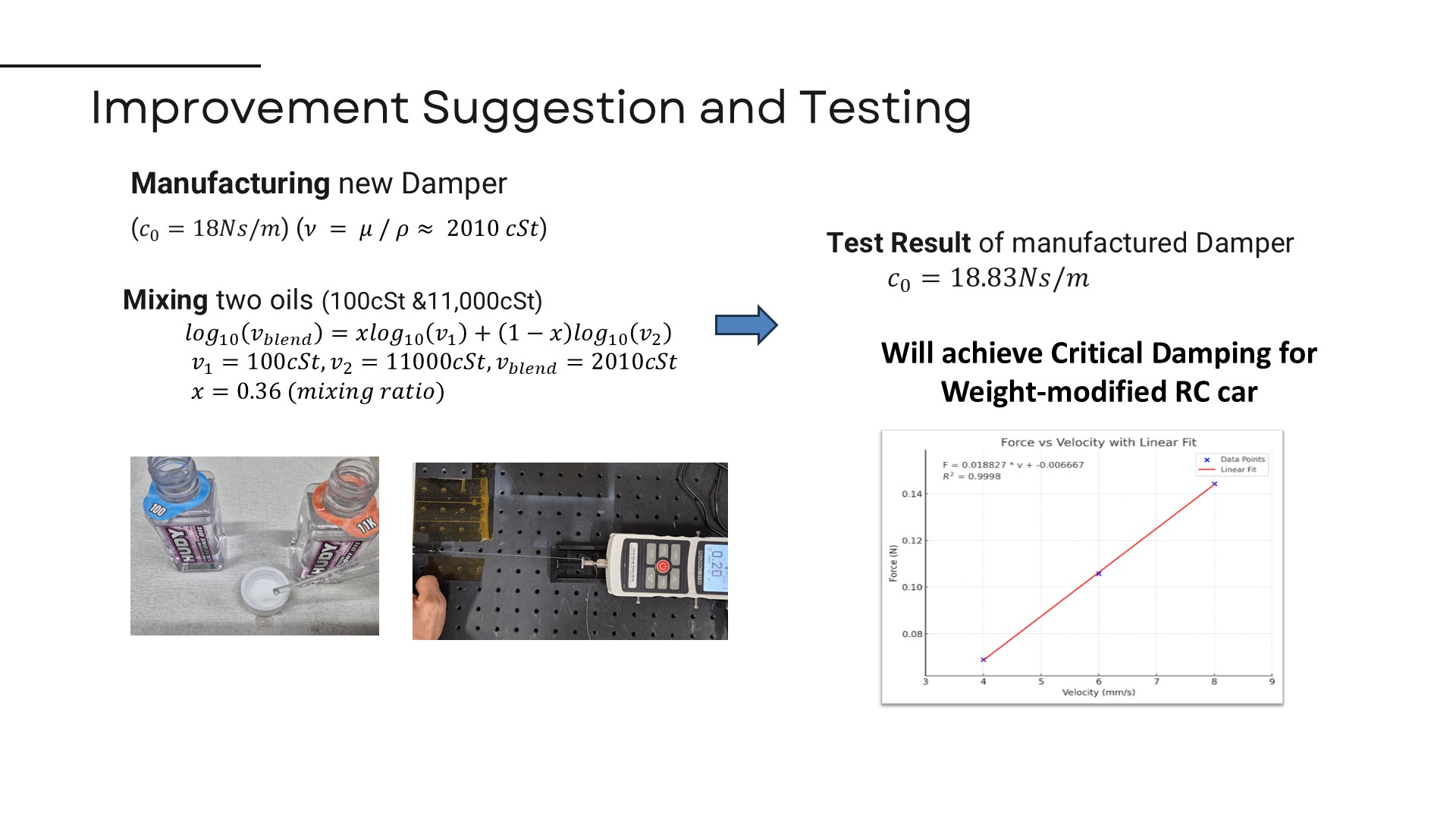

Tested fabricated improvements, including a rear-biased suspension with custom-viscosity oil (2010 cSt) designed to reduce wheel slip and enhance traction.