Auxetic Crashbox Optimization

Developed and analyzed auxetic crashbox structures to enhance vehicle impact energy absorption.

The project involved theoretical modeling, multi-stage optimization (Grid Search, CMA-ES, FEA), and experimental validation using 3D-printed TPU samples.

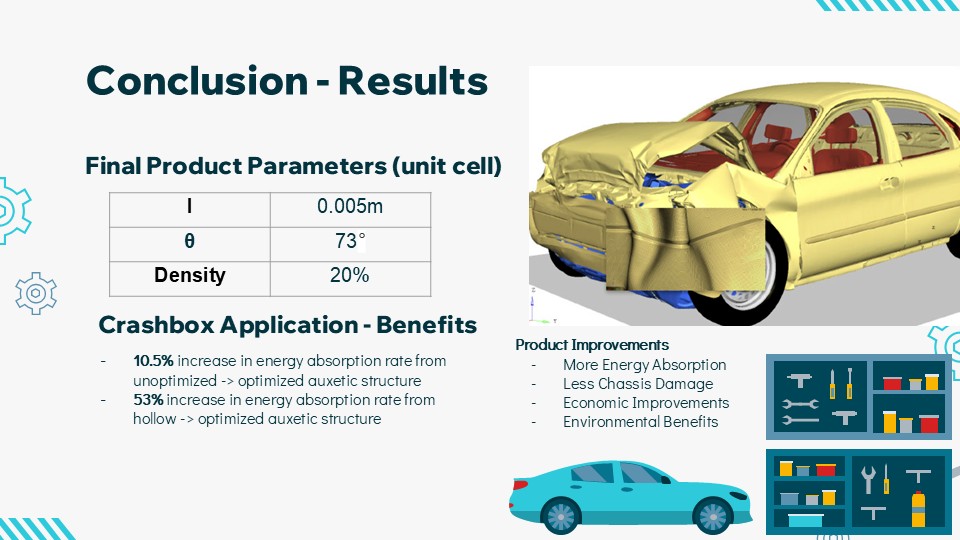

The optimized design achieved a 10.5% increase in energy absorption compared to the unoptimized auxetic design, and a 53% improvement over a hollow crashbox configuration.

Key takeaways:

- Modeled auxetic unit cell behavior and derived Modulus of Resilience (MOR).

- Optimized geometry using Grid Search, CMA-ES, and FEA to maximize energy absorption.

- Verified performance experimentally via compression and impact testing.

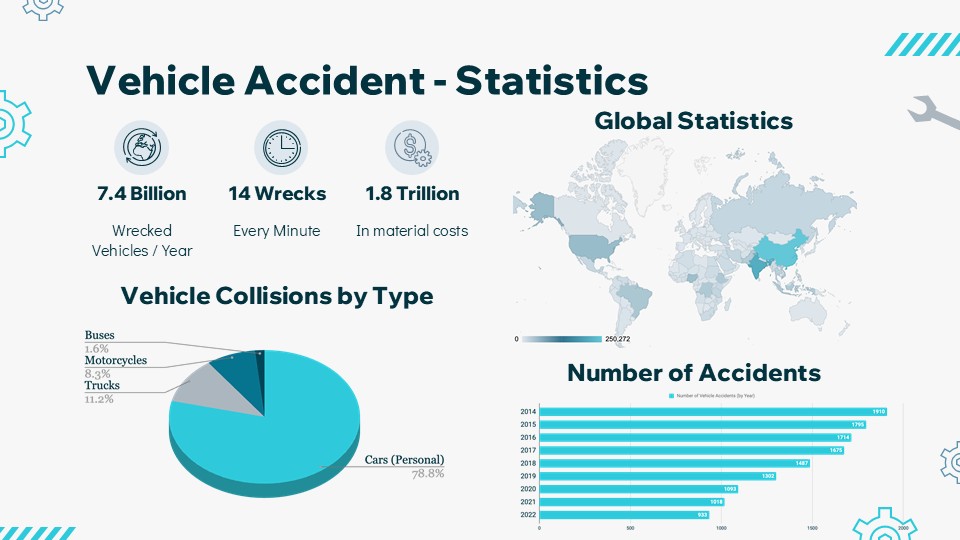

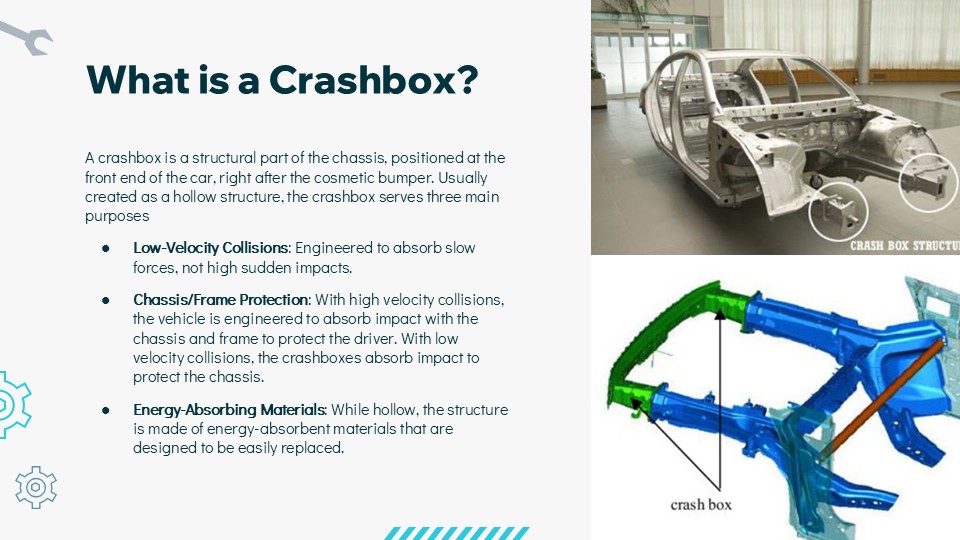

Introduction

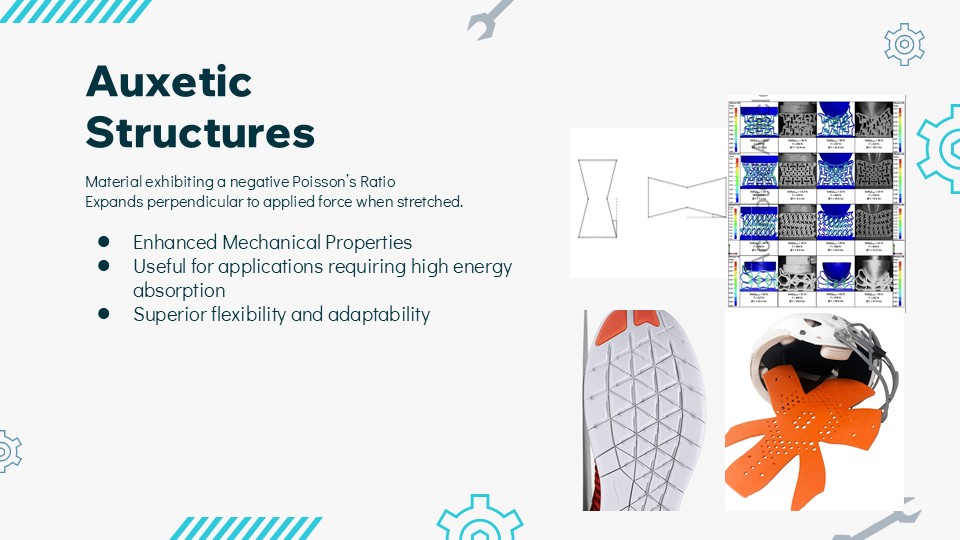

Crashboxes absorb low-velocity collision energy to protect the chassis. Auxetic structures with a negative Poisson’s ratio were introduced to enhance deformation efficiency and energy absorption capacity.

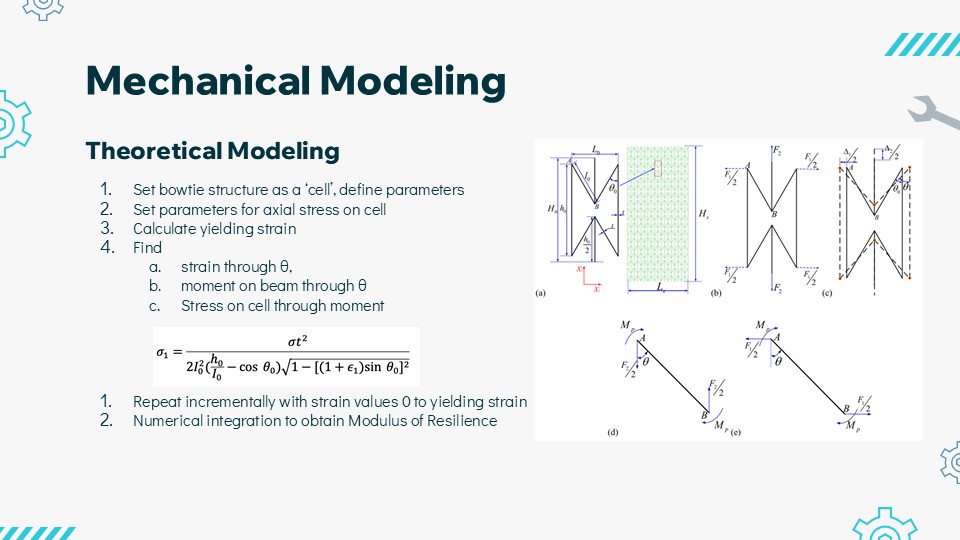

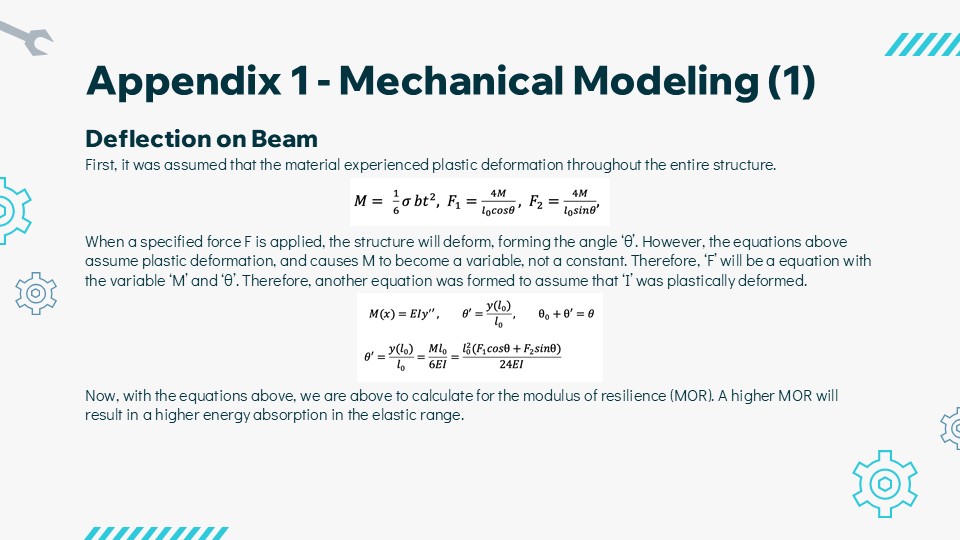

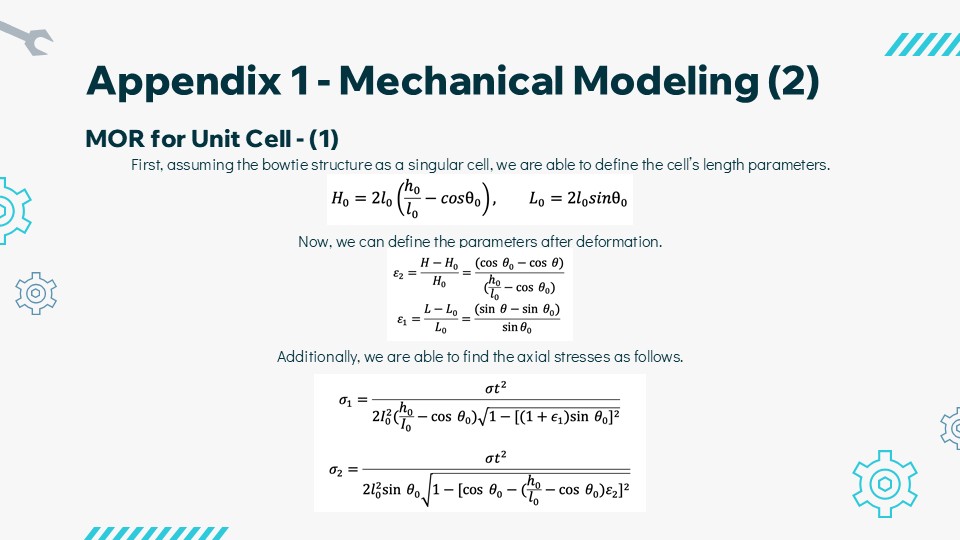

Modeling

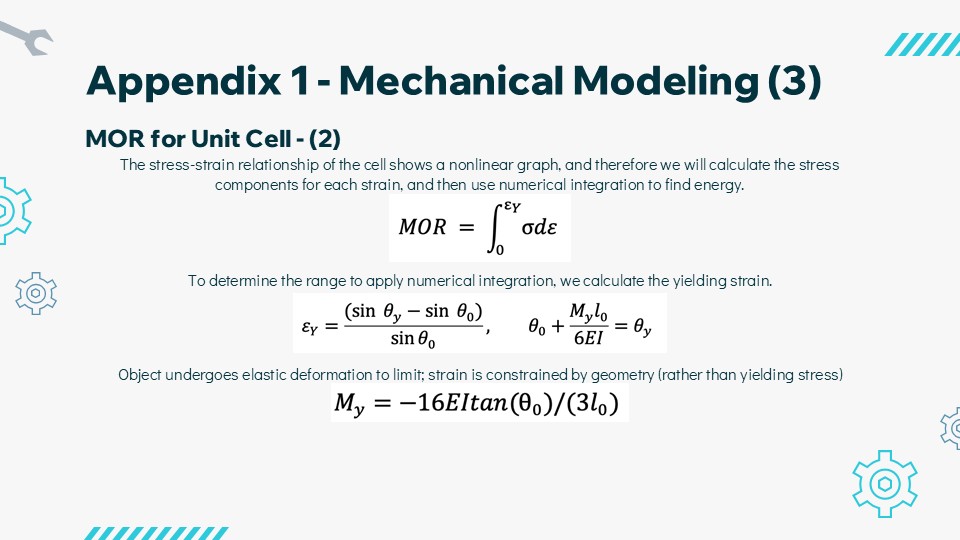

Established mechanical and mathematical models for an auxetic “bow-tie” unit cell. Derived stress–strain relationships and calculated Modulus of Resilience (MOR) through numerical integration.

Optimization

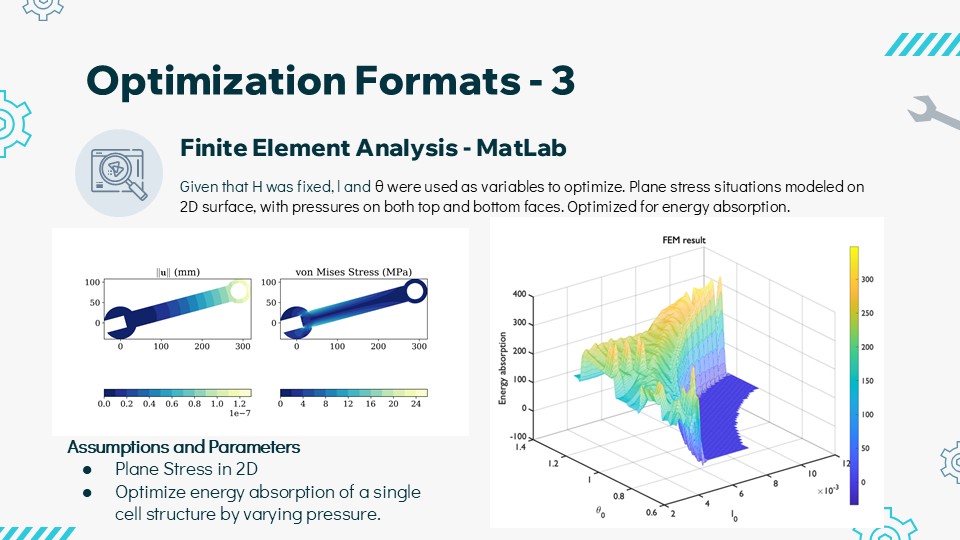

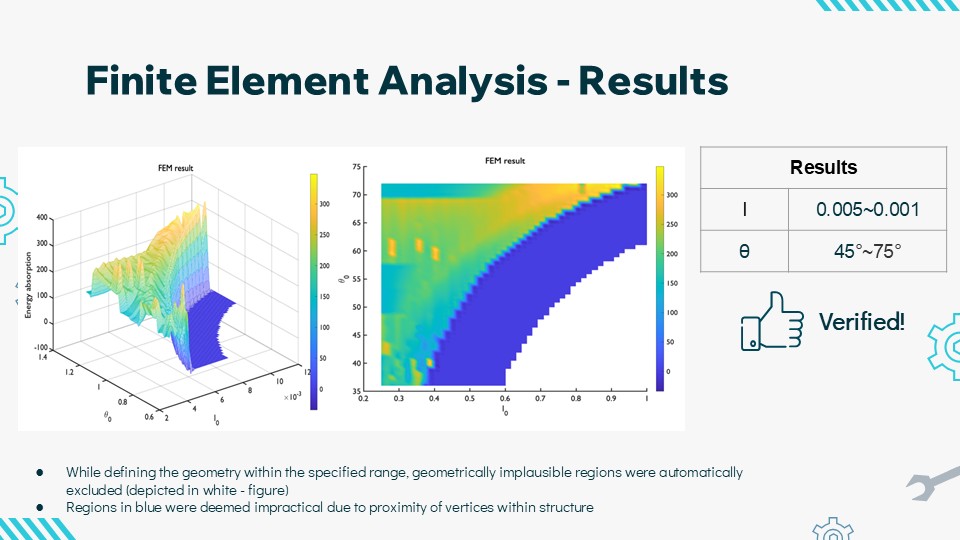

Performed triple-stage optimization:

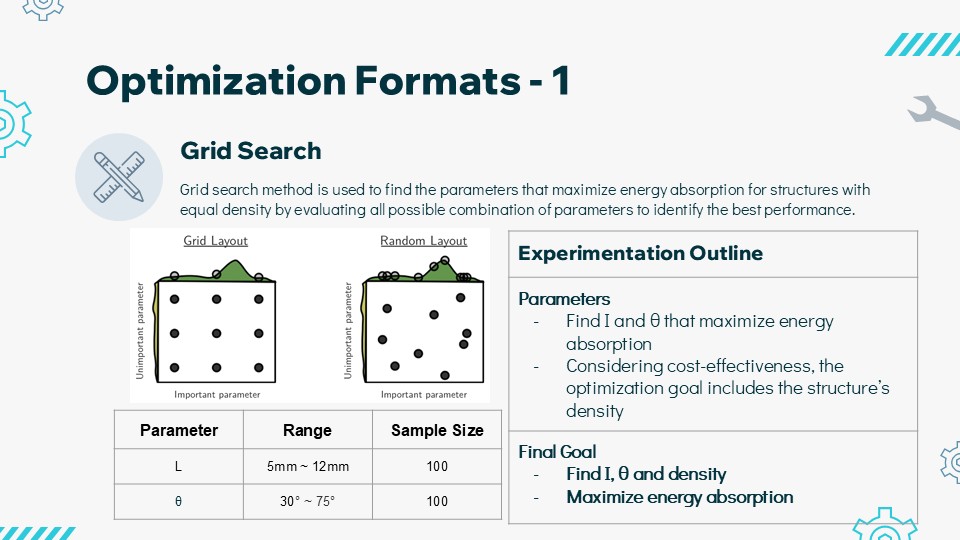

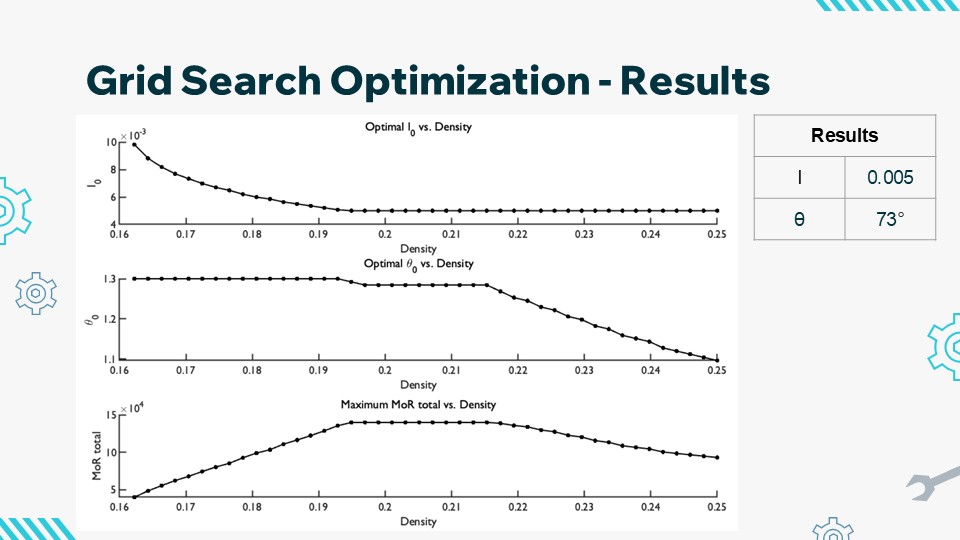

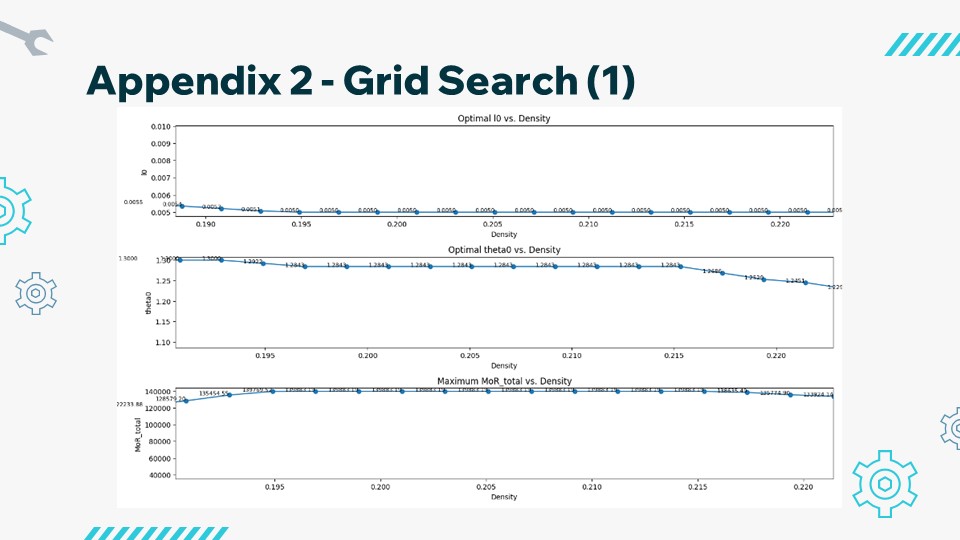

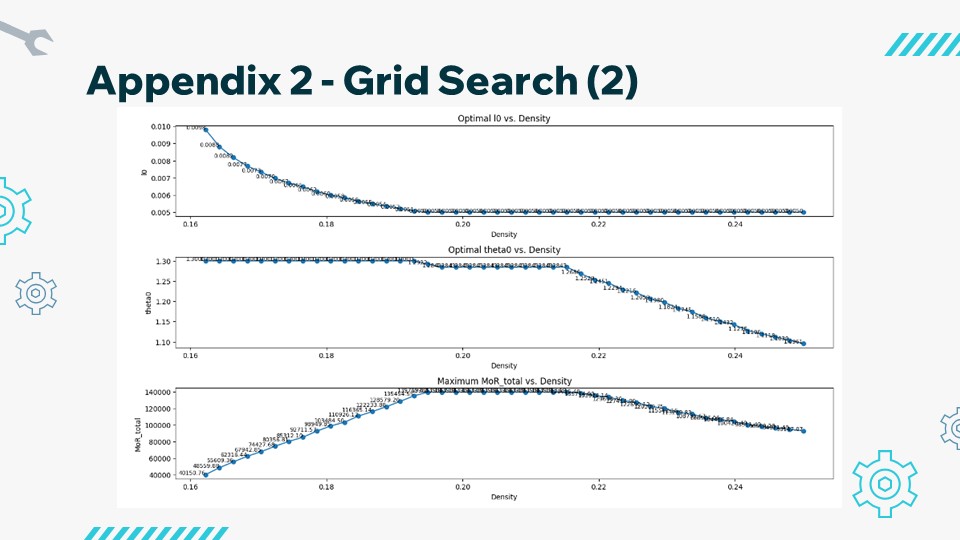

1️⃣ Grid Search for exhaustive parameter evaluation.

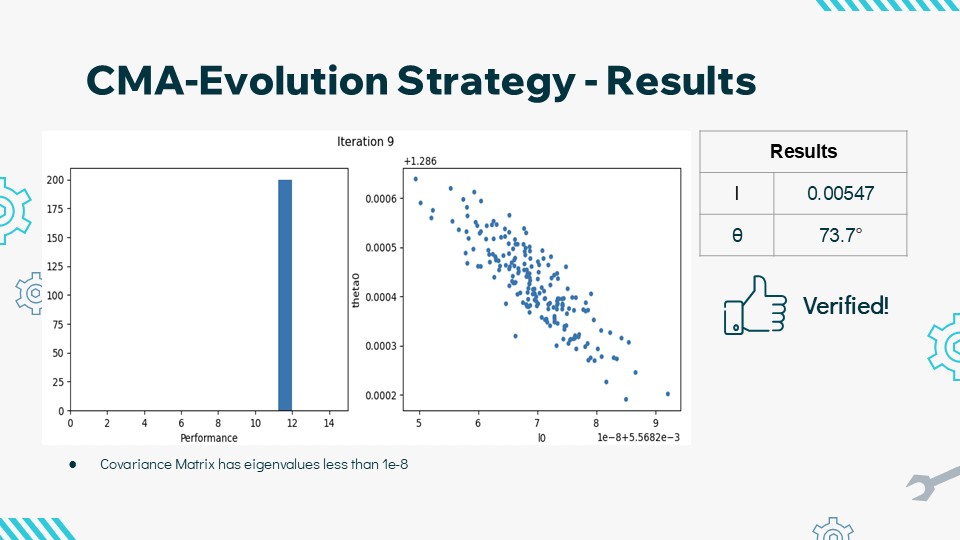

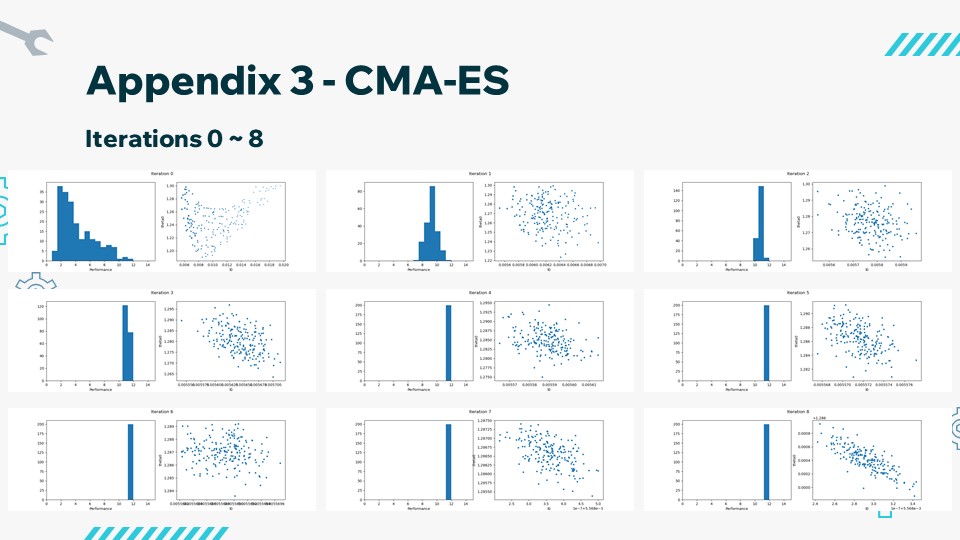

2️⃣ CMA-ES (Covariance Matrix Adaptation Evolution Strategy) for adaptive optimization in multidimensional space.

3️⃣ Finite Element Analysis (FEA) to verify optimized geometry and energy absorption behavior.

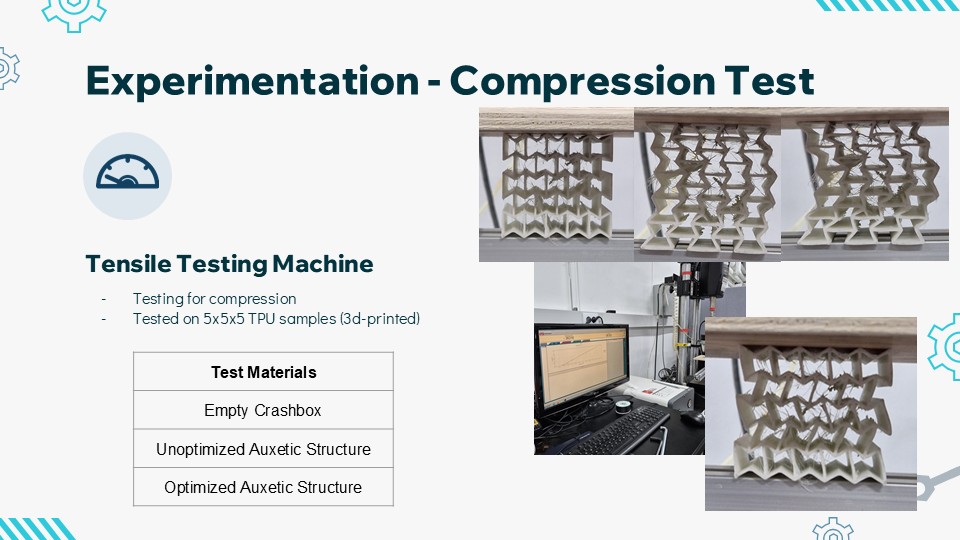

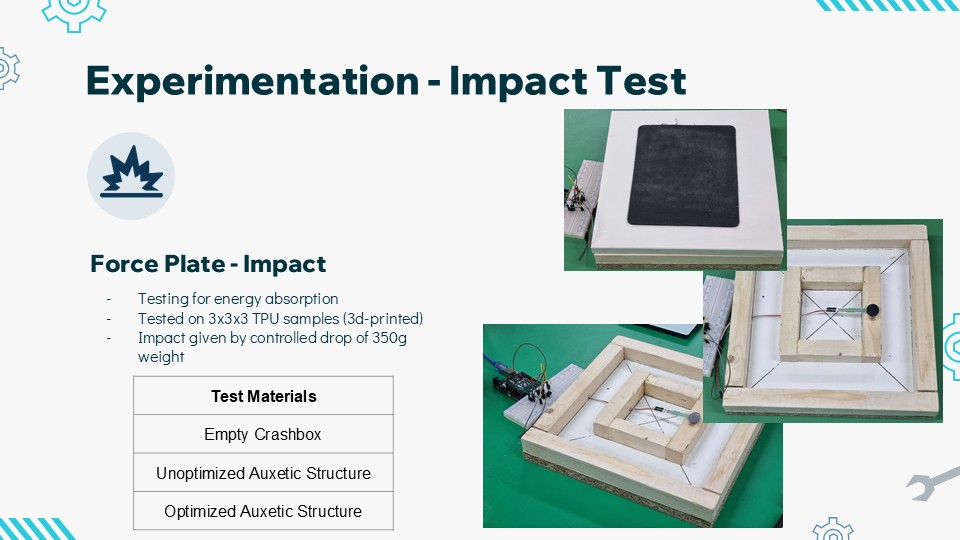

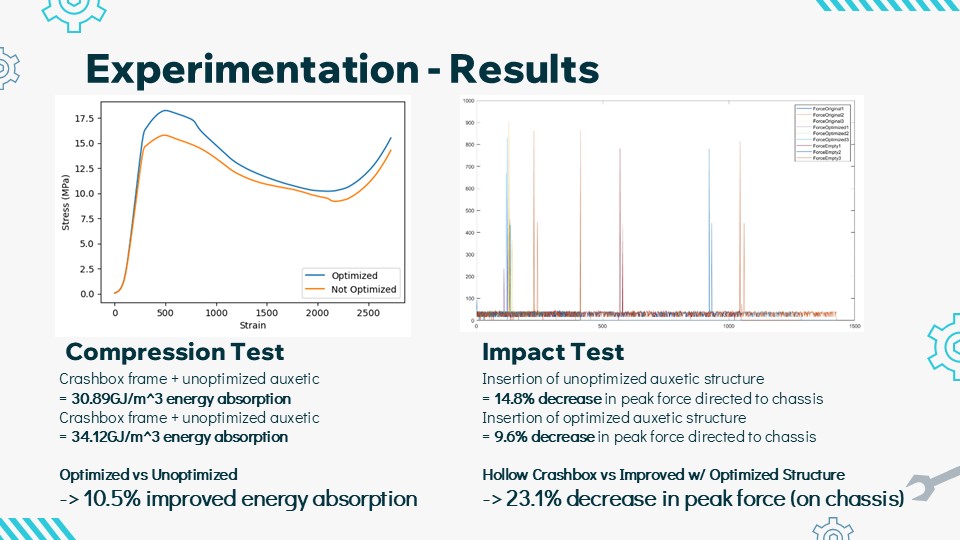

Experimentation

3D-printed TPU samples were tested under compression and impact using a modified tensile press and force plate.

Results showed 10.5% higher energy absorption for optimized auxetic inserts, and 23.1% lower peak force on the chassis compared to hollow crashboxes.

Appendix

Appendix slides summarize the theoretical and mathematical foundations behind the modeling process,

including beam deflection, stress–strain derivations, and Modulus of Resilience (MOR) calculations

used to validate the auxetic crashbox’s mechanical behavior.